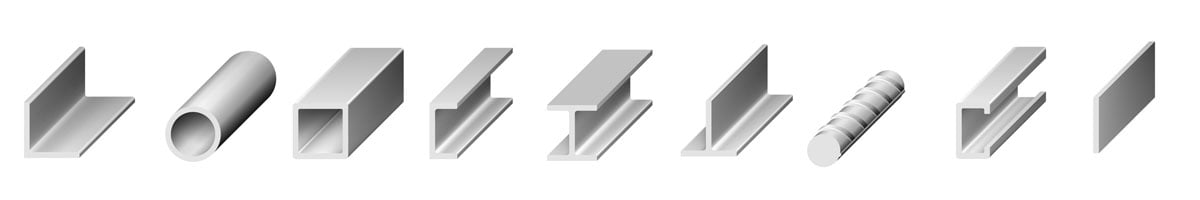

Roll forming changes flat metal strips into complex profiles. This continuous bending operation uses precisely positioned rollers to create everything from simple channels to intricate custom shapes. The process serves industries worldwide.

Unlike other metal forming methods that work with individual pieces, roll forming operates continuously. Metal coil feeds through sequential forming stations, and each station gradually bends the material closer to its final shape. This allows manufacturers to produce consistent, high-quality profiles at remarkable speeds and lengths that would be impossible with traditional forming methods.

The process has changed significantly since its industrial origins in the 19th century. What began as a method for producing simple structural shapes has become a sophisticated manufacturing technique. Modern roll forming combines advanced engineering software, precision tooling, and automated controls. The results are repeatable and meet the demanding requirements of today’s industries.

Roll forming plays a necessary role in modern manufacturing because it offers unique advantages. You can produce very long lengths in a single operation. Material use is excellent. Cross-sectional accuracy stays consistent. The process is also cost-effective for medium to high-volume production. All of these benefits make it the preferred choice for applications ranging from commercial building components to specialized transportation parts.

Ten Point Trim has been perfecting roll forming since 1949. With more than 75 years of experience and continuous innovation, we’ve developed the expertise and capabilities to solve complex forming challenges. We maintain the precision and quality our customers depend on.

How Does the Roll Forming Process Work?

Roll forming changes flat metal strips into finished profiles through progressive metal forming across sequential stations. Unlike stamping or brake forming, which shape metal in discrete steps, roll forming gradually bends the material as it travels through a series of specially designed roller dies.

The process begins with coiled metal stock. The material feeds continuously into the first forming station. Each station contains upper and lower rollers with precisely machined contours that gradually bend specific portions of the material. As the metal progresses through subsequent stations, additional bends are introduced while maintaining previously formed sections. This creates the desired cross-sectional profile.

Material feeding and guidance systems keep consistent positioning and speed throughout the forming process. Advanced electronic roll feed systems, like those used at Ten Point Trim, maintain tolerances as tight as .002 inches. This keeps dimensional accuracy across the entire length of the finished product. Air feed systems provide additional precision for complex profiles requiring exact positioning.

Tool design and setup considerations are critical for successful roll forming. Engineers must carefully plan the progression of bends. They consider material properties, spring-back characteristics, and the sequence of forming operations. Each roller set is precision-machined to specific tolerances. The spacing between stations is calculated to prevent material distortion or unwanted stress concentrations.

Quality control throughout the process involves continuous monitoring of dimensional accuracy, surface finish, and material integrity. Modern roll forming lines include real-time measurement systems that can detect variations and make automatic adjustments to maintain specifications. This continuous quality monitoring means that every foot of material meets the required standards, whether producing a 10-foot section or an 85-foot length.

The entire process operates at production speeds that can exceed 200 feet per minute for simple profiles, which makes roll forming one of the most efficient methods for producing long-length metal components with consistent cross-sectional accuracy.

What Materials Can Be Roll Formed?

Roll forming accommodates an extensive range of materials. This makes it suitable for diverse applications across multiple industries. The process works well with both ferrous and non-ferrous metals. Each offers specific advantages depending on the end-use requirements.

Steel varieties form the backbone of most roll forming operations. Carbon steel provides good strength-to-cost ratios and formability, which makes it ideal for structural applications and general manufacturing. Stainless steel grades—including 201, 301, 304, 409, and 430—offer corrosion resistance for demanding environments like food processing, chemical handling, and marine applications. Pre-galvanized steel combines the strength of steel with better corrosion protection. Pre-painted materials arrive ready for final assembly, eliminating additional finishing steps.

Aluminum options include various alloys chosen for their specific properties. Aluminum’s lightweight characteristics and natural corrosion resistance make it popular for transportation, aerospace, and architectural applications. Different aluminum alloys provide varying levels of strength, formability, and surface finish options. This allows manufacturers to pick the right material selection for each application.

Specialty materials expand roll forming capabilities into specialized markets. Brass and copper offer superior conductivity and corrosion resistance for electrical and plumbing applications. Nitronic 30, a specialized stainless steel alloy, provides exceptional strength and corrosion resistance for marine and industrial environments. High-strength alloys work for components in demanding applications where standard materials cannot meet performance requirements.

Ten Point Trim’s material thickness capabilities range from .010 inches for delicate applications up to .250 inches for heavy-duty structural components. This broad thickness range allows roll forming of everything from thin decorative trim to substantial load-bearing elements.

Width capabilities extend up to 36.25 inches. This accommodates large-scale components while maintaining precision across the entire width. This capability, combined with length capacities exceeding 85 feet, allows production of components that would require multiple pieces or joints with other forming methods.

The selection of appropriate material depends on factors including strength requirements, environmental conditions, appearance specifications, and cost considerations. Ten Point Trim’s experienced team provides guidance on material selection to make sure you get the right performance and cost-effectiveness for each application.

Not sure which material is right for your project? Call (317) 875-5424 and let’s discuss your requirements.

What Products Can Roll Forming Create?

Roll forming creates a diverse array of products across multiple industries. The process works well at producing consistent, complex profiles that would be difficult or impossible to manufacture using other metal forming methods.

Commercial building components represent a significant portion of roll formed products. Elevator components including guide rails, cab frames, and door tracks require precise dimensions and smooth finishes that roll forming delivers consistently. Storage enclosures and shelving systems benefit from roll forming’s ability to create strong, lightweight profiles with integrated mounting features. Conveyor system components rely on roll forming for consistent cross-sections that keep proper belt tracking and smooth operation across long installations.

Rail car components showcase roll forming’s capability to produce large-scale, heavy-duty parts. Roof sheets provide weather protection while maintaining structural integrity across the car’s length. Side sheets and side plates form the primary structural elements of rail car bodies. These require precise dimensions and consistent material properties. Roof purlins, side sills, and inner side sills provide structural support. Side sill top plates add reinforcement at critical stress points.

Transportation applications extend beyond rail cars to include automotive and commercial vehicle components. Structural components and trim pieces benefit from roll forming’s ability to produce parts with consistent cross-sections and good surface finishes. The process allows integration of multiple functions into single components. This reduces assembly time and improves overall vehicle quality.

Solar industry applications have grown significantly as renewable energy installations expand. Mounting systems and structural elements require precision profiles that can withstand environmental stresses while providing secure attachment points for solar panels. Roll forming’s length capabilities are particularly valuable for solar applications. Long spans reduce the number of joints and potential failure points.

Stadium seating represents a specialized application where roll forming creates custom profiles and brackets that combine structural strength with architectural aesthetics. These components must meet strict safety requirements while providing comfortable, durable seating solutions for large venues.

Length capabilities extending beyond 85 feet allow production of components that eliminate joints and connections. This improves both structural integrity and appearance. This capability is particularly valuable for architectural applications, transportation equipment, and industrial installations where continuous lengths provide superior performance.

Need a custom profile for your application? Call (317) 875-5424 for a consultation.

What Are the Benefits of Roll Forming?

Roll forming offers compelling advantages that make it the preferred manufacturing method for a wide range of applications. These benefits combine to deliver superior value for customers while allowing design possibilities that other forming methods cannot match.

Cost efficiency for medium to high volume runs stems from roll forming’s continuous operation and minimal material waste. Unlike stamping, which requires individual blanks and generates significant scrap, roll forming works directly from coiled stock and produces virtually no waste material. Tooling costs are typically lower than stamping dies, especially for complex profiles. The ability to produce multiple profiles on the same equipment further reduces per-part costs.

Superior material use results from the continuous feeding process and precise material control. Roll forming can achieve material use rates exceeding 95%, compared to 70-80% for typical stamping operations. This efficiency translates directly to cost savings, particularly important when working with expensive materials like stainless steel or specialized alloys.

Consistent precision and repeatability are built into the roll forming process. Once properly set up, roll forming lines can produce thousands of feet of material with dimensional variations measured in thousandths of an inch. This consistency eliminates the part-to-part variation common in other forming processes and reduces or eliminates secondary operations like machining or grinding.

Complex profiles are possible in a single operation through the progressive forming action of multiple stations. Roll forming can create profiles with multiple bends, varying wall thicknesses, and integrated features like holes, notches, or embossed patterns. This capability reduces assembly requirements and improves overall product quality by eliminating potential alignment issues between separate components.

Long lengths without joining represent one of roll forming’s most distinctive advantages. Where other processes might require welding or mechanical joining of shorter sections, roll forming can produce continuous lengths limited only by handling and transportation considerations. This capability eliminates potential weak points and creates superior structural performance while reducing labor costs associated with joining operations.

The combination of these benefits makes roll forming particularly attractive for applications requiring consistent quality, cost-effectiveness, and design flexibility. Industries from construction to transportation rely on these advantages to deliver superior products while maintaining competitive pricing.

How Does Roll Forming Compare to Other Metal Forming Processes?

Understanding how roll forming compares to alternative metal forming processes helps manufacturers select the right method for their specific applications. Each process offers distinct advantages depending on factors like part geometry, production volume, material requirements, and cost considerations.

Roll forming versus press brake forming reveals significant differences in capabilities and applications. Press brake forming works well for low-volume production and parts requiring very sharp bends or complex angular relationships. Roll forming provides superior speed and consistency for longer production runs. Where press brake forming might produce 20-50 parts per hour, roll forming can generate hundreds of feet per hour of continuous product. Roll forming also maintains better dimensional consistency across long lengths, while press brake parts may show slight variations from piece to piece.

Roll forming versus stamping highlights different strengths for different applications. Stamping works well for parts requiring complex shapes in multiple planes or those needing tight dimensional control in all directions. Roll forming works best when length is a primary requirement, offering capabilities that stamping simply cannot match. Length capabilities extend beyond 85 feet compared to stamping’s typical maximum of a few feet. Tooling costs for roll forming are often lower than stamping dies, particularly for complex profiles, though setup costs may be higher for very short runs.

When to choose roll forming depends on several key factors. Production volume requirements favor roll forming for medium to high-volume applications where the process setup costs can be spread across many parts. Length requirements strongly favor roll forming when continuous lengths provide structural or aesthetic advantages. Complexity considerations support roll forming when profiles require multiple bends or integrated features that would require secondary operations with other processes.

Material thickness and width requirements also influence process selection. Roll forming handles a broad range of thicknesses from .010″ to .250″ and widths up to 36.25″, covering most structural and architectural applications. Very thin materials or extremely thick sections might require specialized approaches.

Cost analysis must consider both tooling costs and production costs. Roll forming typically shows advantages for production runs exceeding several thousand feet. The continuous operation and high material use offset the initial setup investment. Shorter runs might favor press brake or other methods with lower setup costs.

The decision depends on balancing these factors against specific application requirements. Roll forming provides the best solutions for applications requiring long lengths, consistent cross-sections, and cost-effective production of medium to high volumes.

What Roll Forming Equipment Does Ten Point Trim Use?

Ten Point Trim operates advanced roll forming equipment designed to handle diverse customer requirements while maintaining exceptional precision and quality. Our equipment lineup positions us to tackle projects ranging from delicate thin-gauge materials to heavy-duty structural components.

Our facility features 16 roll forming lines with spindles ranging from 1.5 inches to 3.5 inches in diameter. This variety allows us to match equipment capabilities precisely to project requirements. This keeps the right forming conditions for each application. Smaller spindle lines work well with thin materials and tight radius bends. Larger spindle equipment handles heavier gauges and provides the forming power needed for challenging materials.

The heavy-duty 20-stand Tishken line represents our flagship capability. It features 3.5-inch diameter spindles capable of rolling materials up to 36.25 inches wide and .250 inches thick. This substantial equipment includes a 40-inch straightener that keeps material flatness before forming begins. This is critical for maintaining dimensional accuracy across the full width of large components. The line also includes a 100-ton pre-notch press and a 150-ton cutoff press. This allows complete processing of complex parts without material handling between operations.

Pre and post-punch operations use presses ranging from 40 tons to 300 tons. This provides the capability to add holes, notches, or other features either before or after the roll forming process. This flexibility allows creation of finished parts ready for assembly, eliminating secondary operations and reducing overall production costs. The variety of press capacities means we can handle everything from delicate piercing operations to heavy-duty structural modifications.

Electronic roll feed and air feed systems maintain positioning accuracy to .002-inch tolerances. This keeps dimensional consistency across the entire length of each part. These precision feeding systems automatically compensate for material variations and maintain consistent feed rates regardless of production speed. This level of control is needed for meeting the tight tolerances required in applications like elevator components and transportation equipment.

Material handling capabilities include a sophisticated overhead hoist system featuring a 20-foot spreader bar and vacuum grippers capable of handling sections weighing over 1,000 pounds. This equipment allows safe, efficient handling of large components while protecting surface finishes. The vacuum gripper system eliminates the marking or damage that can occur with mechanical lifting devices. This is particularly important for pre-finished materials or components requiring pristine surface conditions.

This equipment suite, combined with our experienced team, allows Ten Point Trim to handle virtually any roll forming challenge while maintaining the quality and precision our customers depend on.

Questions about whether roll forming is right for your project? Our experienced team can help you evaluate your options.

Why Is Indiana an Ideal Location for Roll Forming Manufacturing?

Indiana’s strategic position and manufacturing heritage create significant advantages for roll forming operations. These benefits help customers across North America and beyond. The state’s central location and robust infrastructure provide logistical benefits that translate directly to improved service and reduced costs for customers nationwide.

Central location advantages place Indiana within one day’s truck delivery of major metropolitan areas and industrial centers throughout the Midwest, East Coast, and Southeast. This positioning reduces transportation costs and delivery times compared to coastal manufacturing locations. It also provides access to major rail networks that serve transcontinental routes. For customers requiring just-in-time delivery or frequent shipments, Indiana’s location minimizes logistics complexity and costs.

A manufacturing heritage runs deep in Indiana, as well. Established supply chains support metalworking and precision manufacturing and generations of skilled, experienced workers understand the importance of quality, precision, and reliability that roll forming applications demand. The state’s educational institutions continue developing skilled technicians and engineers. This keeps a steady pipeline of talent for advanced manufacturing operations.

Logistics benefits extend beyond geographic location to include proximity to major rail lines, interstate highways, and shipping routes. Indiana’s transportation infrastructure supports efficient movement of both raw materials and finished products. Multiple routing options provide flexibility and reliability. The state’s position along major freight corridors keeps competitive shipping rates and transit times.

The skilled workforce advantage reflects Indiana’s long-standing commitment to manufacturing. Workers understand the precision required for complex roll forming operations and the quality standards that customers expect. This experience base reduces training time for new projects and keeps consistent performance across different applications and industries.

Cost advantages compared to coastal manufacturing centers include lower facility costs, reduced labor expenses, and competitive utility rates. These savings can be passed along to customers while maintaining healthy margins for continued investment in equipment and capabilities. The lower cost structure also provides flexibility during economic fluctuations, helping maintain competitive pricing when market conditions become challenging.

Ten Point Trim’s Zionsville facility shows these Indiana advantages. We’re strategically located to serve diverse industries across North America. Our central position allows efficient service to customers from automotive manufacturers in the Southeast to rail car builders in the West. We maintain the cost effectiveness that keeps projects competitively priced. This location, combined with our equipment capabilities and experienced team, positions us to deliver superior value regardless of where our customers are located.

What Custom Services Does Ten Point Trim Offer?

Ten Point Trim provides custom services that extend far beyond basic roll forming operations. We deliver complete solutions that streamline our customers’ manufacturing processes and reduce their overall project costs and complexity.

In-house design and engineering support begins with initial concept discussions and continues through final production. Our experienced engineers work closely with customers to understand their specific requirements. We then develop forming solutions that improve both performance and manufacturing efficiency. This collaborative approach often identifies opportunities to consolidate multiple components into single roll formed parts. This reduces assembly time and improves overall product quality.

Tool and die shop capabilities allow us to design, build, and maintain forming tools entirely in-house. This control over the tooling process keeps the right tool design for each application while providing rapid response for modifications or repairs. In-house tooling also allows us to maintain certain profiles with little or no tooling cost to customers, particularly for commonly requested shapes or modifications of existing designs.

AutoCAD design services provide detailed technical drawings and specifications that integrate seamlessly with customer design processes. Our CAD capabilities include 3D modeling for complex profiles and complete documentation packages for quality control and manufacturing processes. These detailed drawings keep clear communication of requirements and specifications throughout the production process.

Inventory storage and just-in-time delivery services help customers manage their material flow and reduce carrying costs. We can store finished products until needed, then deliver on predetermined schedules that match customer production requirements. This service is particularly valuable for customers with limited storage space or those requiring steady material flow for continuous production operations.

Bar coding and SPC (Statistical Process Control) systems provide complete traceability and quality documentation for every order. Bar coding allows efficient tracking of materials and finished products through our facility and into customer operations. SPC systems continuously monitor critical dimensions and process parameters. This provides documentation that products meet specifications while identifying trends that might indicate process adjustments are needed.

Ink jet printing and labeling services add identification, specifications, or customer-specific markings directly to finished products. This capability eliminates secondary labeling operations and keeps identification readable throughout handling and installation. Custom labeling can include part numbers, specifications, installation instructions, or any other information customers require.

These services change Ten Point Trim from a simple manufacturing vendor into a strategic partner that contributes to overall project success while reducing customer costs and complexity.

How Do I Get Started with a Roll Forming Project?

Starting a roll forming project with Ten Point Trim begins with understanding your specific requirements and translating those needs into manufacturable solutions. Our streamlined process keeps efficient project development from initial concept through final delivery.

Project planning and design considerations start with defining the profile requirements, including cross-sectional shape, dimensional tolerances, material specifications, and length requirements. Consider how the roll formed component will integrate with other parts of your assembly, including connection methods, mounting requirements, and any special features needed. Early consultation with our engineering team can identify opportunities to improve the design for roll forming while meeting all functional requirements.

Information needed for accurate quoting includes detailed drawings or sketches showing the desired profile, dimensional tolerances that must be maintained, material specifications including grade and finish requirements, quantity requirements for initial orders and anticipated ongoing volumes, and timeline requirements for tooling development and production startup. If you have samples of existing parts or competitive products, these can provide valuable reference information for developing quotations.

Additional considerations include any special features like holes, notches, or surface treatments that might affect the forming process or require secondary operations. Packaging and shipping requirements should also be discussed early, particularly for long lengths or products requiring special handling to protect surface finishes.

Timeline expectations vary depending on project complexity, but typical projects follow predictable phases. Tool design and fabrication generally requires 4-8 weeks for standard profiles, with more complex shapes potentially requiring additional time. Once tooling is complete, sample parts can typically be produced within days for customer approval. Production startup follows sample approval, with delivery schedules depending on order quantities and current production loading.

Ready to explore how roll forming can benefit your project? Contact Ten Point Trim today to discuss your requirements with our experienced team. We’re committed to delivering the precision, quality, and service that helps you deliver on your promises to your customers.

Request a quote online or call to schedule a consultation with our team. With more than 75 years of roll forming expertise, we’re ready to help solve your most challenging requirements.